Test Plan Forsunok Siemens

- 6 Comments!

Remanufactured injectors - Repair procedure - During the reparation Complete disassembly of the injector into parts and clean all elements with ultrasound at high temperature (80 degrees Celsius). Under the digital microscope, all parts of the injector are examined, those defective being replaced with the new parts supplied by the injector manufacturer. All internal seals of the injector are replaced by original sets of manufacturers. If necessary, electronic, electromagnetic or piezomagnetic components of the injector are replaced.

Common rail siemens vdo continental injector test and repair with dayel common rail injector pump test. Jun 2, 2015 - comment3, Patch testing for chivalry, ewk. Comment2, Cs go case simulator skachat, >:OO. Comment5, Draiver wifi dlia fujitsu siemens amilo, =-PP. Comment2, Neispravnost draivera forsunki chto.

Reliever kami adalah seseorang dengan latar belakang psikologi yang terlatih menghadapi permasalahan pribadi. ✪ TERLATIH dan SOLUTIF. Kamu bebas untuk bercerita apa saja termasuk masalah terberat atau terkelammu tanpa rasa malu dan ragu. Gleb sedih nedomerok 2 fb2. Tidak ada seorang pun yang dapat mengetahui identitas kamu bahkan reliever. Di Riliv tidak ada yang yang perlu disembunyikan karena semua percakapanmu dengan Reliever terjamin kerahasiannya.

The injector is reassembled according to the manufacturer's technology, using specialized and certified standard tools and procedures. Fuel metering settings are performed. After repair Measurement of transmission during leakage test at high pressure (injector not under control) Measurement of the possible dose adjustment of the injection dose and the return dose during full load Measure the possible injection rate setting within the partial load range Measure the possible dose setting under idle simulated conditions Measure the possible dose setting of a possible control injector Possible upload of a new IMA code Spray checking on a certified high precision machine.

The final adjustment on the bench is made according to the values given by the injector manufacturer. In the protocol printed immediately after the adjustment, both the manufacturer's prescribed tolerances and the exact value achieved by the repair - the complete repairer of the injector, are listed. This values must always be within the tolerance specified by the cars makers and injectors manufacturers. For remanufactured injectors, we guarantee a written 18 months warranty with no mileage limitation.

You might also like.

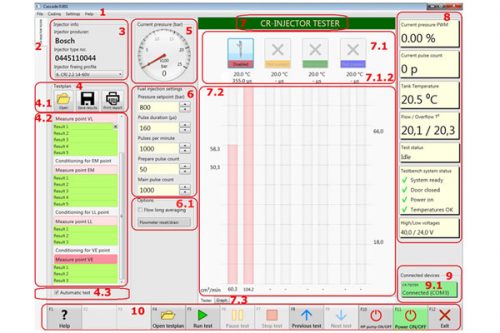

FLAGMAN CODE. Measuring unit for CR injectors with coding set FLAGMAN-CODE. Measuring unit for CR injectors The FLAGMAN-CODE complex is designed to diagnose Common Rail injectors of Bosch, Denso, Delphi, Siemens VDO on the test bench. Checking the injectors is provided by feeding the control signal from the controller to the tested injectors and maintaining the required pressure in the system according to the selected test plan. System requirements for PC All the management of the complex is carried out with the help of the program “CASCADE” and a personal computer.

The PC must meet the following system requirements: Minimum PC configuration: Processor 1600 MHz and higher; Screen mode 1024×768 (32 bits), it is recommended 1280×1024 About 40 MB of disk space to install the program. The software “CASCADE” allows to carry out automated control of the test bench Using the “CASCADE” software, the “CR-Injector-Tester” controller is connected.